Computerized Maintenance Management System: The Definitive Guide

Streamline maintenance, optimize assets & boost efficiency with Computerized Maintenance Management System. A comprehensive guide to implementation, features, and alternatives.

Welcome to the definitive guide on Computerized Maintenance Management System (CMMS)! In today’s fast-paced business environment, organizations are constantly seeking ways to streamline their maintenance operations, optimize asset performance, and drive overall efficiency. That’s where CMMS comes into play as a powerful solution that revolutionizes the way maintenance tasks are managed.

In this comprehensive guide, we will delve into the intricacies of CMMS, exploring its key features, benefits, and implementation strategies. Whether you’re a small business owner looking to enhance maintenance practices or a facility manager aiming to optimize maintenance schedules, this guide will equip you with the knowledge and insights necessary to make informed decisions.

We will unravel the mysteries behind CMMS, from its fundamental concepts to advanced functionalities. Discover how CMMS can help you effectively track work orders, manage assets, streamline preventive maintenance, and generate insightful reports for data-driven decision-making. Moreover, we will explore real-world case studies and success stories, showcasing the tangible impact that CMMS can have on organizations of all sizes and industries.

So, whether you’re a maintenance professional seeking to upgrade your systems or an executive searching for ways to boost operational efficiency, this definitive guide will serve as your roadmap to unlocking the full potential of a Computerized Maintenance Management System. Get ready to embark on an enlightening journey that will transform the way you approach maintenance and propel your organization toward greater success. Let’s dive in!

What is a Computerized Maintenance Management System (CMMS)?

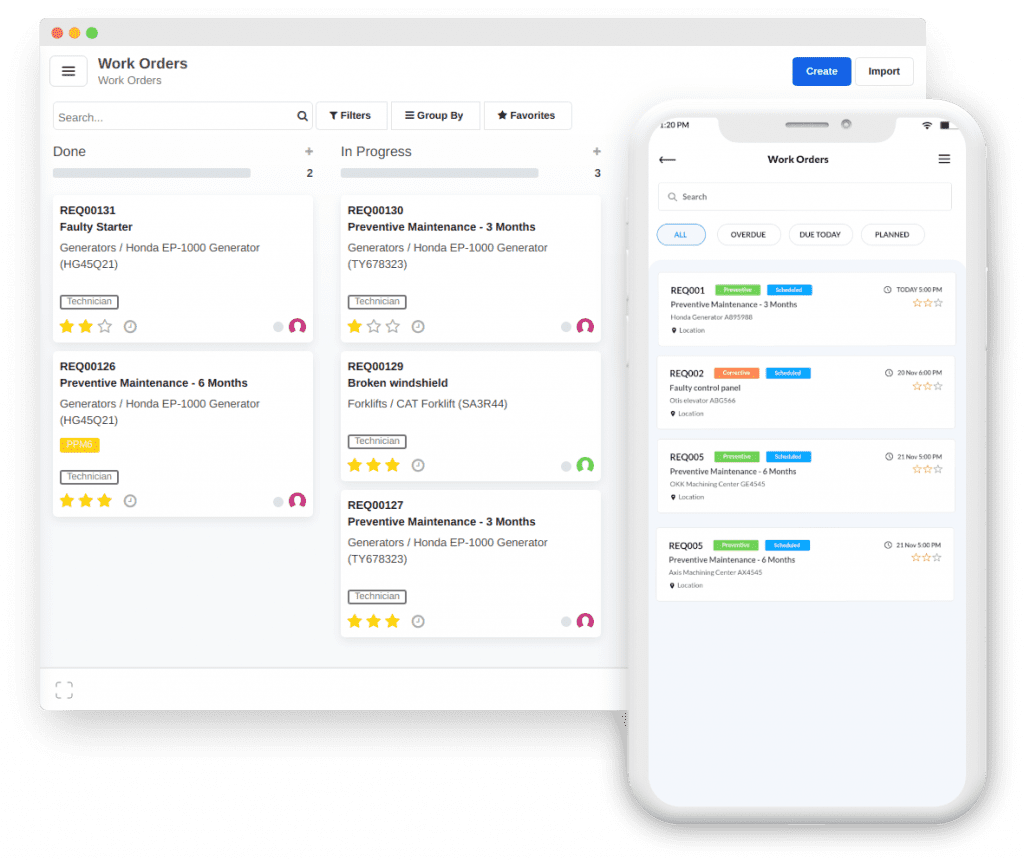

A Computerized Maintenance Management System (CMMS) is a robust software solution designed to streamline and optimize maintenance operations within an organization. It serves as a centralized hub for managing and tracking maintenance tasks, work orders, assets, inventory, and overall maintenance activities. By digitizing and automating various maintenance processes, CMMS empowers businesses to enhance efficiency, reduce downtime, and maximize the lifespan of their assets.

At its core, a CMMS enables maintenance teams to transition from traditional paper-based or manual systems to a modern, data-driven approach. It replaces tedious manual record-keeping and cumbersome spreadsheets with a user-friendly interface, offering a wealth of features and functionalities tailored specifically for maintenance management.

Key Features of a CMMS

A comprehensive CMMS typically encompasses a wide range of features to address the diverse needs of maintenance operations. These may include:

1. Work Order Management

CMMS allows users to create, assign, and track work orders, ensuring that maintenance tasks are efficiently executed, monitored, and documented. It facilitates seamless communication and collaboration between team members, enabling real-time updates and status tracking.

2. Asset Management

With CMMS, organizations can effectively manage their assets throughout their lifecycle. It provides a centralized database to track asset details, maintenance history, warranties, and service schedules. This enables proactive maintenance planning, optimized resource allocation, and improved asset performance.

3. Preventive Maintenance

CMMS empowers businesses to implement proactive maintenance strategies by scheduling and automating preventive maintenance tasks. By conducting regular inspections, servicing, and replacements based on predefined schedules, organizations can minimize unplanned downtime, extend asset lifespan, and prevent costly breakdowns.

4. Inventory Management

CMMS offers inventory management capabilities, ensuring that spare parts and supplies are readily available when needed. It helps optimize inventory levels, streamline procurement processes, and reduce the risk of stockouts or excess inventory.

5. Reporting and Analytics

CMMS provides robust reporting and analytics features to generate insightful maintenance performance reports. These reports offer key metrics, trends, and data visualizations that help identify bottlenecks, track maintenance costs, measure equipment reliability, and make data-driven decisions for continuous improvement.

The Benefits of Implementing a CMMS

Implementing a CMMS brings numerous benefits to organizations of all sizes and industries. Some of the key advantages include:

Enhanced Efficiency

CMMS automates manual processes, streamlines workflows, and eliminates paperwork, saving time and effort for maintenance teams. It enables swift communication, seamless task allocation, and timely completion of maintenance activities.

Reduced Downtime

By implementing preventive maintenance strategies, CMMS helps organizations proactively identify and resolve potential issues before they escalate into costly breakdowns. This minimizes unplanned downtime and improves asset availability.

Optimized Resource Allocation

CMMS provides visibility into resource availability, skill sets, and workload distribution. It helps organizations allocate resources effectively, preventing underutilization or overloading of maintenance personnel.

Improved Asset Performance

By tracking maintenance history, scheduling preventive maintenance, and conducting timely repairs, CMMS ensures that assets operate at their peak performance. This extends their lifespan, reduces the frequency of breakdowns, and maximizes return on investment.

Regulatory Compliance

CMMS enables organizations to maintain accurate records, generate audit trails, and adhere to regulatory requirements. It helps demonstrate compliance with industry standards, safety regulations, and maintenance protocols.

In the next sections of this guide, we will explore the implementation process, best practices, and real-world examples of how organizations have successfully leveraged CMMS to achieve significant improvements in their maintenance operations. So, let’s continue our journey to unlock the full potential of a Computerized Maintenance Management System.

Transform Your Maintenance Operations

Start your journey towards efficient maintenance and improved productivity with BriskForce CMMS. Sign up for a free trial now!

How to Implement a Computerized Maintenance Management System (CMMS)?

Implementing a Computerized Maintenance Management System (CMMS) requires careful planning, collaboration, and attention to detail. By following best practices and a well-defined implementation process, organizations can ensure a smooth transition and successful adoption of CMMS. Let’s explore the key steps involved in implementing a CMMS effectively.

- Define Objectives and Scope: Start by clearly defining your objectives for implementing a CMMS. Identify the pain points and areas of improvement within your maintenance operations. Determine the scope of your implementation, such as the specific departments or facilities that will be included.

- Conduct a Needs Assessment: Perform a thorough needs assessment to understand your organization’s requirements and the functionalities you need from a CMMS. Involve key stakeholders, including maintenance managers, technicians, and IT personnel, to gather insights and align priorities.

- Research and Select the Right CMMS: Conduct research to identify CMMS solutions that align with your needs. Evaluate factors such as ease of use, scalability, integration capabilities, and customer support. Request demos and trial periods to assess the software’s functionality and suitability for your organization.

- Plan for Data Migration: If you have existing maintenance data, plan for its migration to the CMMS. Ensure data accuracy, cleanliness, and compatibility with the new system. Consider engaging the CMMS vendor or a data migration specialist to assist with the process.

- Establish Implementation Team and Roles: Form an implementation team comprising representatives from various departments, including maintenance, IT, and management. Assign roles and responsibilities, ensuring clear communication channels and accountability throughout the implementation process.

- Configure CMMS to Match Requirements: Work closely with the CMMS vendor or implementation team to configure the system according to your organization’s specific needs. Customize data fields, workflows, user permissions, and reports to align with your maintenance processes.

- Provide Comprehensive Training: Invest in comprehensive training for all users of the CMMS, including maintenance technicians, supervisors, and administrators. Ensure that they understand the system’s functionalities, workflows, and how to effectively utilize the software to achieve their objectives.

- Pilot Testing and Refinement: Before full deployment, conduct a pilot test of the CMMS in a controlled environment. Identify a subset of users or a specific facility to test the system’s functionality, workflows, and integration with existing processes. Gather feedback, address any issues, and refine the system based on user experiences.

- Data Validation and Integration: Validate the data within the CMMS to ensure accuracy and consistency. Integrate the CMMS with other relevant systems, such as asset management software, ERP systems, or IoT platforms, to enable seamless data exchange and enhance maintenance insights.

- Develop Documentation and Standard Operating Procedures (SOPs): Document the CMMS configuration, workflows, and standard operating procedures to serve as a reference for users. Create user manuals, training materials, and FAQ documents to facilitate ongoing support and knowledge sharing.

- Go-Live and Continuous Improvement: Once the system is fully tested and validated, schedule the go-live date for the CMMS implementation. Monitor the system closely during the initial phase, address any issues promptly, and gather feedback for continuous improvement.

- Ongoing Maintenance and Support: Establish a system for ongoing maintenance, upgrades, and technical support. Regularly review and optimize CMMS performance, incorporate user feedback, and stay updated with new features and industry best practices.

By following these steps and adopting best practices, organizations can successfully implement a CMMS and unlock its full potential to enhance maintenance efficiency, reduce downtime, and maximize asset performance. Remember that effective change management, user adoption, and continuous improvement are key factors in realizing the long-term benefits of a Computerized Maintenance Management System.

Alternatives to Computerized Maintenance Management System

While Computerized Maintenance Management Systems (CMMS) are widely used and offer comprehensive solutions for maintenance management, there are alternative approaches and tools that organizations can consider based on their specific needs. Here are a few alternatives to CMMS:

Enterprise Asset Management (EAM) Systems

Enterprise Asset Management systems provide a broader scope than CMMS, focusing on managing the entire lifecycle of assets across an organization. EAM systems integrate maintenance management with other aspects such as procurement, financials, and asset performance analysis, offering a more holistic approach to asset management.

Maintenance Management Software (MMS)

Maintenance Management Software is a more streamlined alternative to CMMS, focusing primarily on maintenance planning, work order management, and asset tracking. MMS solutions are often user-friendly and easier to implement, making them suitable for smaller organizations with simpler maintenance needs.

Work Order Management Tools

Work Order Management tools specifically cater to managing and tracking work orders, without the extensive functionalities of a full-fledged CMMS. These tools simplify work order creation, assignment, and tracking, providing a focused solution for organizations primarily concerned with work order management.

Asset Performance Management (APM) Systems

Asset Performance Management systems go beyond maintenance management to focus on optimizing asset performance and reliability. APM solutions integrate data from various sources, including maintenance records, real-time sensor data, and predictive analytics, to provide insights for proactive maintenance, condition monitoring, and asset optimization.

Facilities Management Software

Facilities Management Software is designed to manage and track various aspects of facility operations, including maintenance, space management, vendor management, and more. While it may not offer the same depth of maintenance-specific features as CMMS, it provides a broader solution for facility management needs.

Custom-Built Solutions

Some organizations with unique maintenance requirements or complex workflows may opt for custom-built software solutions tailored to their specific needs. These solutions are designed from scratch to address the organization’s specific maintenance management challenges, but they typically require more time, resources, and technical expertise to develop and maintain.

It’s important to carefully evaluate the specific needs and goals of your organization when considering alternatives to CMMS. Factors such as the size of the organization, the complexity of maintenance processes, integration requirements, and budget will play a significant role in determining the most suitable alternative solution. Consulting with industry experts, conducting thorough research, and engaging in vendor demos and trials can help you make an informed decision.

Conclusion

In conclusion, implementing a Computerized Maintenance Management System (CMMS) can bring numerous benefits to organizations seeking to optimize their maintenance operations. With its powerful features and functionalities, a CMMS can streamline workflows, improve asset performance, reduce downtime, and enhance overall operational efficiency. By centralizing maintenance data, automating processes, and providing actionable insights, CMMS empowers organizations to make data-driven decisions, allocate resources effectively, and implement proactive maintenance strategies.